| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | OEM |

| Model Number : | geotube |

| Certification : | ISO,SGS |

| Price : | negotiation |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 600000 Piece/Pieces per Month |

| Delivery Time : | 5-8 days |

OEM Mine Sludge Dewatering Geotextile Tube Sand Bag Geo Container Geotube for Breakwater Embankment Cofferdam Jetty Riverbank

Product Description

Production:

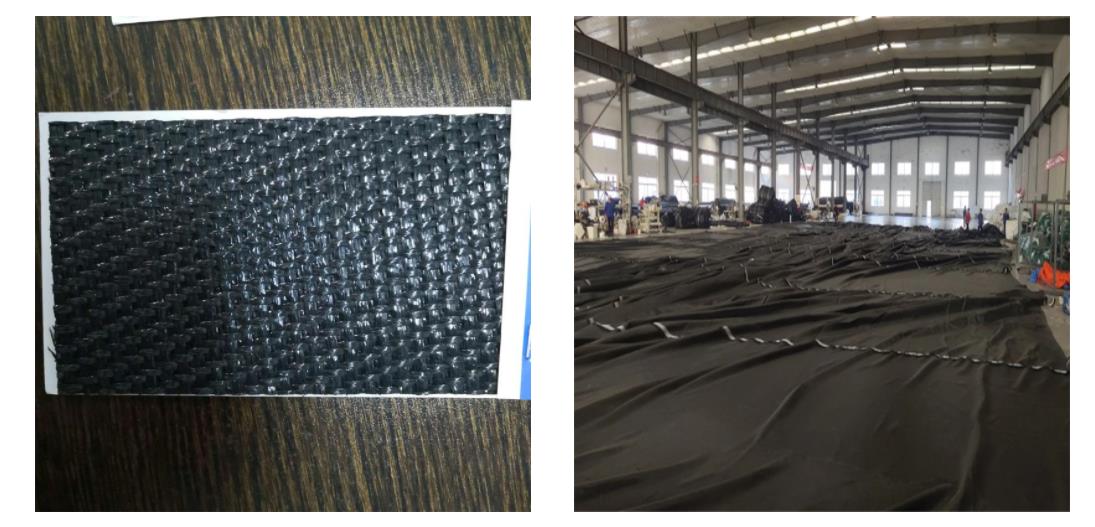

1.Geotextile Tube is manufactured from woven high tenacity

polypropylene multifilament yarns, which are woven into a stable

network such that the yarns retain their relative position.

2.It is inert to biological degradation and resistant to naturally encountered chemicals, alkalis and acids, etc.

3.Geotextile tube has different strength and permeability, and have high UV resistance, seawater resistance, microbial erosion resistance and other durability.

| Item | Unit | Testing Standard | Technical Parameters | ||

| GT70X95B | GT70X95 | ||||

| Breaking strength | MD | KN/m | ISO 10319-2015 | 85 | 85 |

| CD | KN/m | ISO 10319-2015 | 105 | 115 | |

| Elongation of break | MD | % | ISO 10319-2015 | 13 | 13 |

| CD | % | ISO 10319-2015 | 8 | 8 | |

| Sewing Tensile Strength | KN/m | ISO 10321-2008 | 70 | 90 | |

| Static Bursting Strength(CBR) | KN | GB/T 14800-2010 | 8 | 9 | |

| Equivalent hole size(O90) | mm | GB/T 14799-2005 | 0.5 | 0.45 | |

| Permeability(Q50) | L/m2/s | GB/T 15789-2005 | 50 | 35 | |

| UV-resistance (500 Hours strength retention) | % | ASTMD4355-2014 | 90 | 90 | |

This knowledge technology have a three-step process:

Step 1: Filling -- Sludge (dredged material) is pumped into the

Geotube container. Environmentally-safe polymers are added to the

sludge, which makes the solids bind together and water separate.

The TenCate Geotube?container's unique fabric confines the fine

grains of the material.

Step 2: Dewatering -- Clear effluent water simply drains from the

Geotube container through the small pores in the specially

engineered textile. This results in effective dewatering and

efficient volume reduction of the contained materials. And this

volume reduction allows for the repeated filling of the Geotube

container. Over 99% of solids are captured, and clear filtrate can

be collected and recirculated through the system. The decanted

water is often of a quality that can be reused/returned for

processing or returned to native waterways without additional

treatment.

Step 3: Consolidation -- After the final cycle of filling and

dewatering, the solids remain in the bag and continue to densify

due to desiccation as residual water vapor escapes through the

fabric. Volume reduction can be as high as 90 percent. When full,

the Geotube container and contents can be deposited at a landfill,

remain on-site, or the solids can be removed and land-applied when

appropriate.

FAQ

Q: Can you send samples?

|